Quality By Design Safety By Design Environmental Impact Reduction

QUALITY BY DESIGN

Through our company processes and procedures and as an ISO-9001 certified company, we are committed to quality by meeting and surpassing customer satisfaction expectations and producing reliable products.

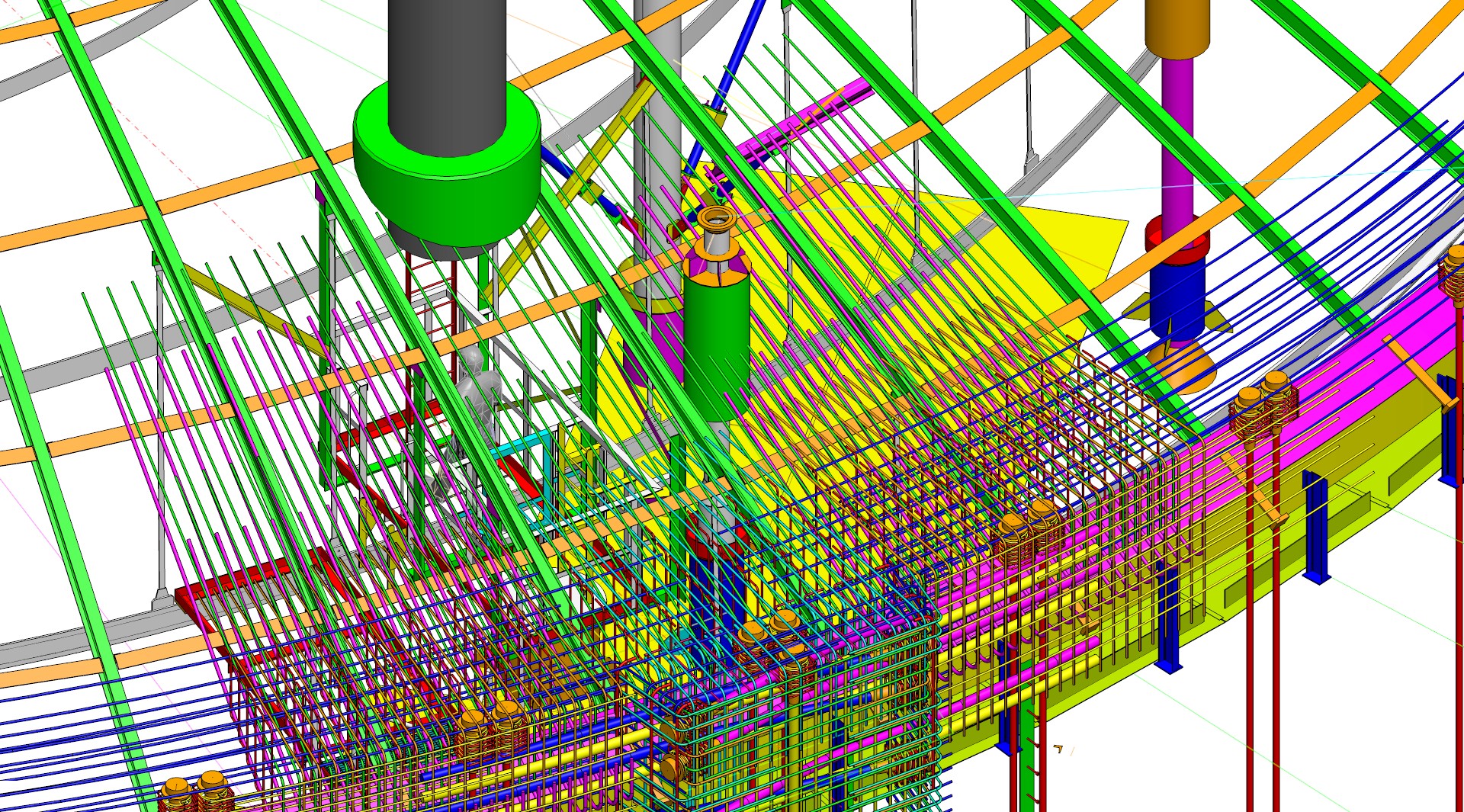

Within our design process, we have an in-depth knowledge of and work to the particular codes and standards required by the region, country and by our clients. In establishing our customer needs, we are able to ensure we meet or exceed their requirements. When applying international standards such as EN 14620, API 625, ACI 376 or GB/T 50938, our clients can always be ensured that we will always achieve the quality required through our design processes.

Utilising control procedures, we ensure that all our designs are thoroughly and rigorously verified and approved.

SAFETY BY DESIGN

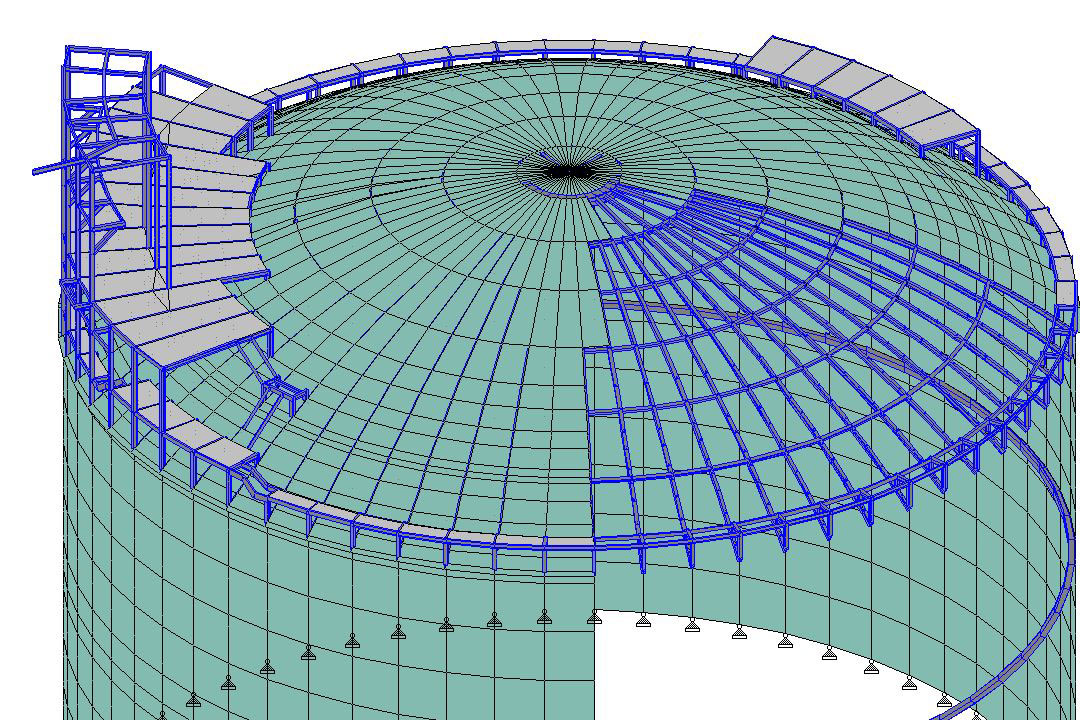

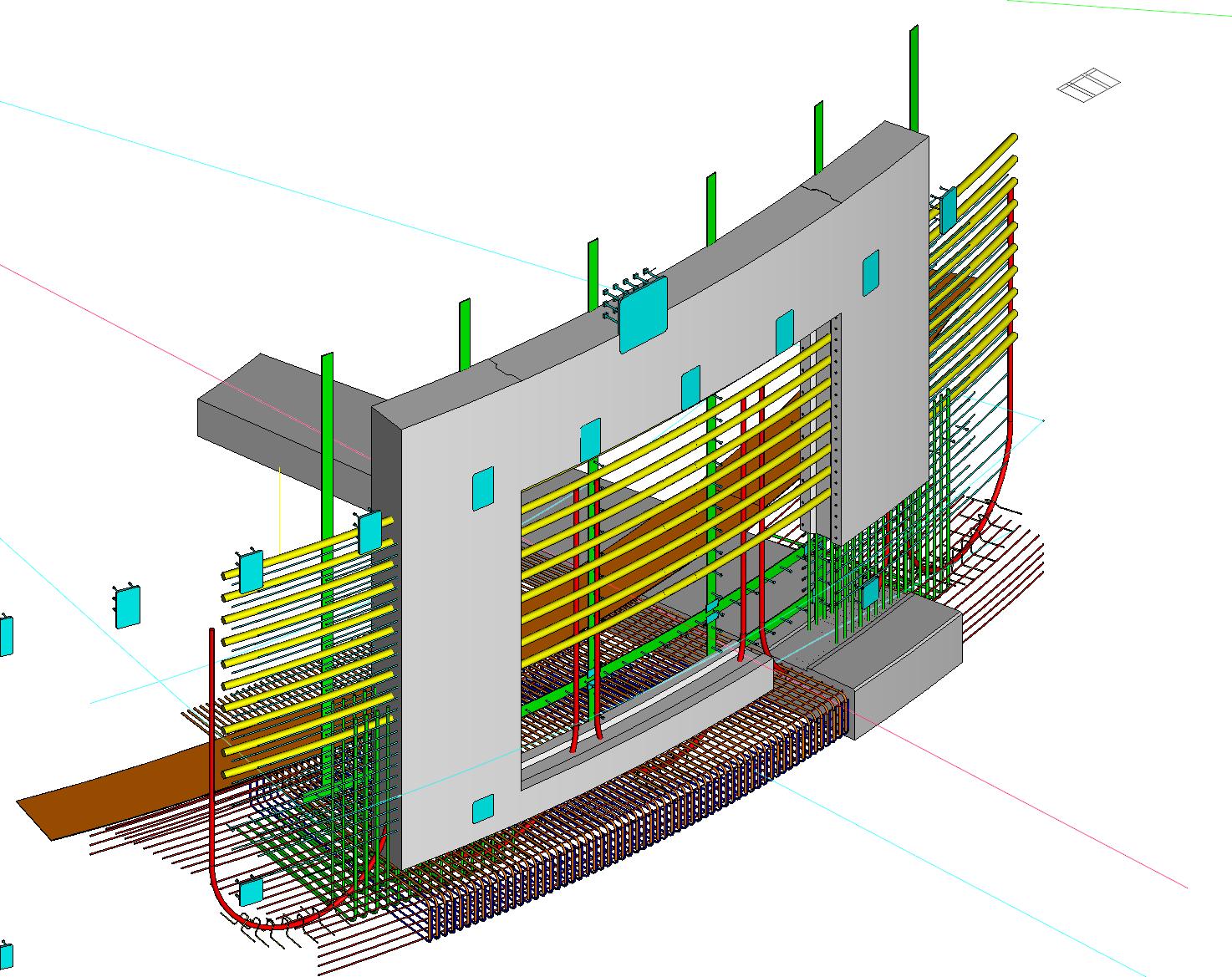

For the storage of refrigerated cryogenic liquid products, full containment storage tanks are commonly designed to EN 14620, API 625, ACI 376 or GB/T 50938 .

The basic design concept of these tanks is to have an inner tank, the primary container, storing the liquefied medium, protected by the secondary outer tank container mitigating against loss of containment, constructed from carbon steel or prestressed concrete.

The primary and secondary containment of a full containment tank must be designed to be liquid tight, with no liquid being present in the annular space between the inner and outer shell under all operational conditions.

The secondary outer tank protects the primary container from external hazards, such as fire, flying objects, blast wave and earthquake impacts, major spills of the cryogenic medium, and serves also as shield to the environment from internal hazards such as leakage of the primary container.

Given the nature of concrete materials, a secondary containment designed and constructed from prestressed concrete, provides an enhanced safety standard for the structure and, even more important, a much higher protection of the environment, the population and infrastructure in the vicinity of the storage tanks.

ENVIRONMENTAL IMPACT REDUCTION

Although, we operate within the liquefied gas industry we continually strive to minimise our environmental impact in whatever we do. For our designs, we optimise the tank design so that we minimise the amount of raw materials required for its construction. This not only minimises the impact on the environment but lowers the cost of construction. Our designs also incorporate bi-products or waste of other processes which would have been discarded otherwise, such as fly ash.

And in the office, we are keen on minimising our environmental impact. We look to re-use or recycle any waste materials and items produced within the office. Old PCs are donated to charities for renovation and re-use. And as we continue to shift to better digital platforms and tools, we move towards our paperless office.